R&D

R&D Capabilities

DEVELOPMENT

1Thermal Management System

With over 40 years of expertise and know-how, we possess optimal thermal management system design capabilities for all platforms, including internal combustion engines, hybrid vehicles, electric vehicles, and hydrogen fuel cell vehicles, contributing to extended driving range and improved durability.

-

4

Types of Powertrain Applied

(ICE / HEV / BEV / FCEV) -

40 +

Years of TMS Research

and Development -

25mil+

Thermal Management Parts

Produced Every Year

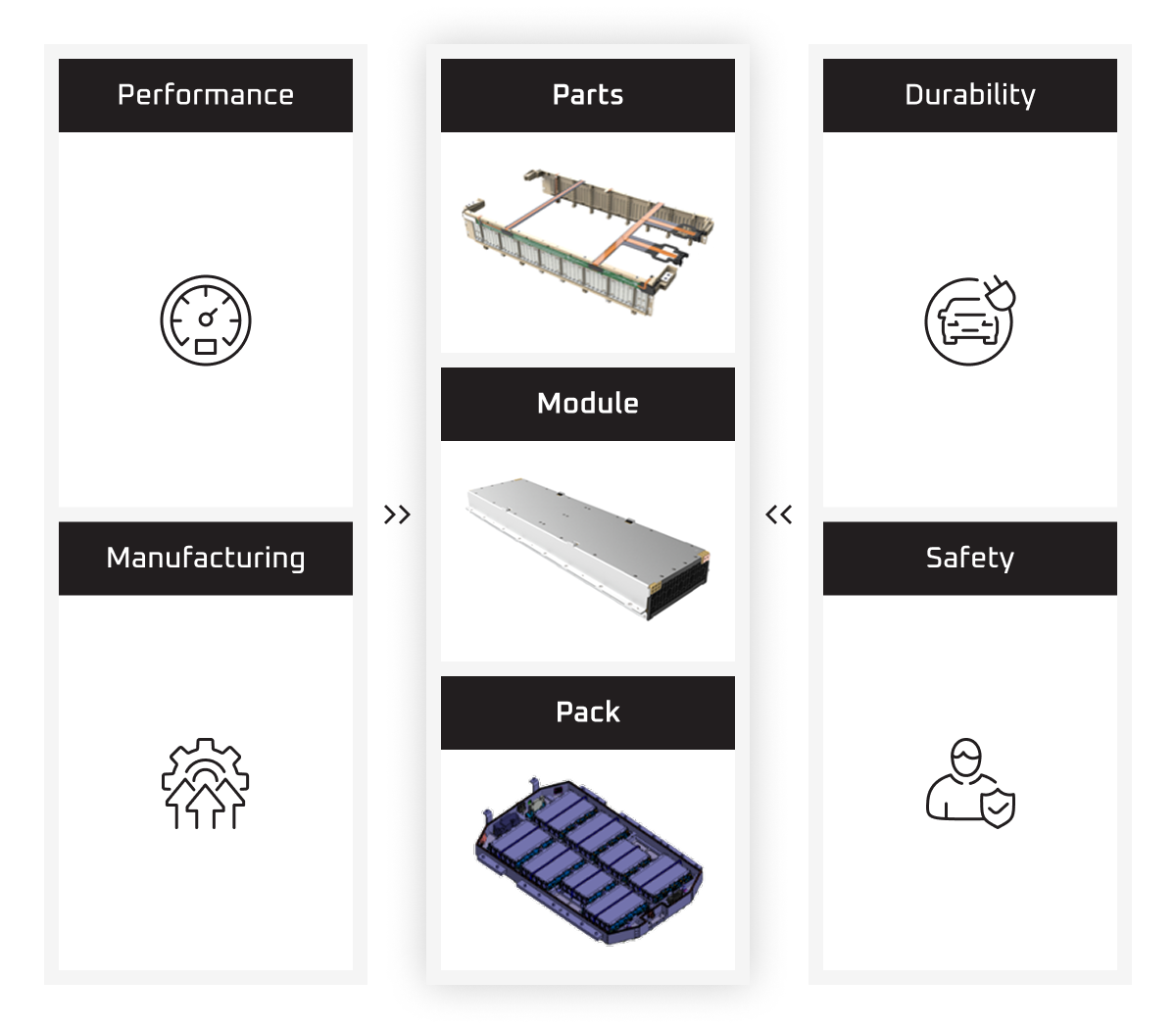

2Battery System

We are capable of designing and developing battery system components, modules, and packs, offering solutions for performance improvement, enhanced safety, and cost reduction, and are recognized by global customers through rigorous testing and validation.

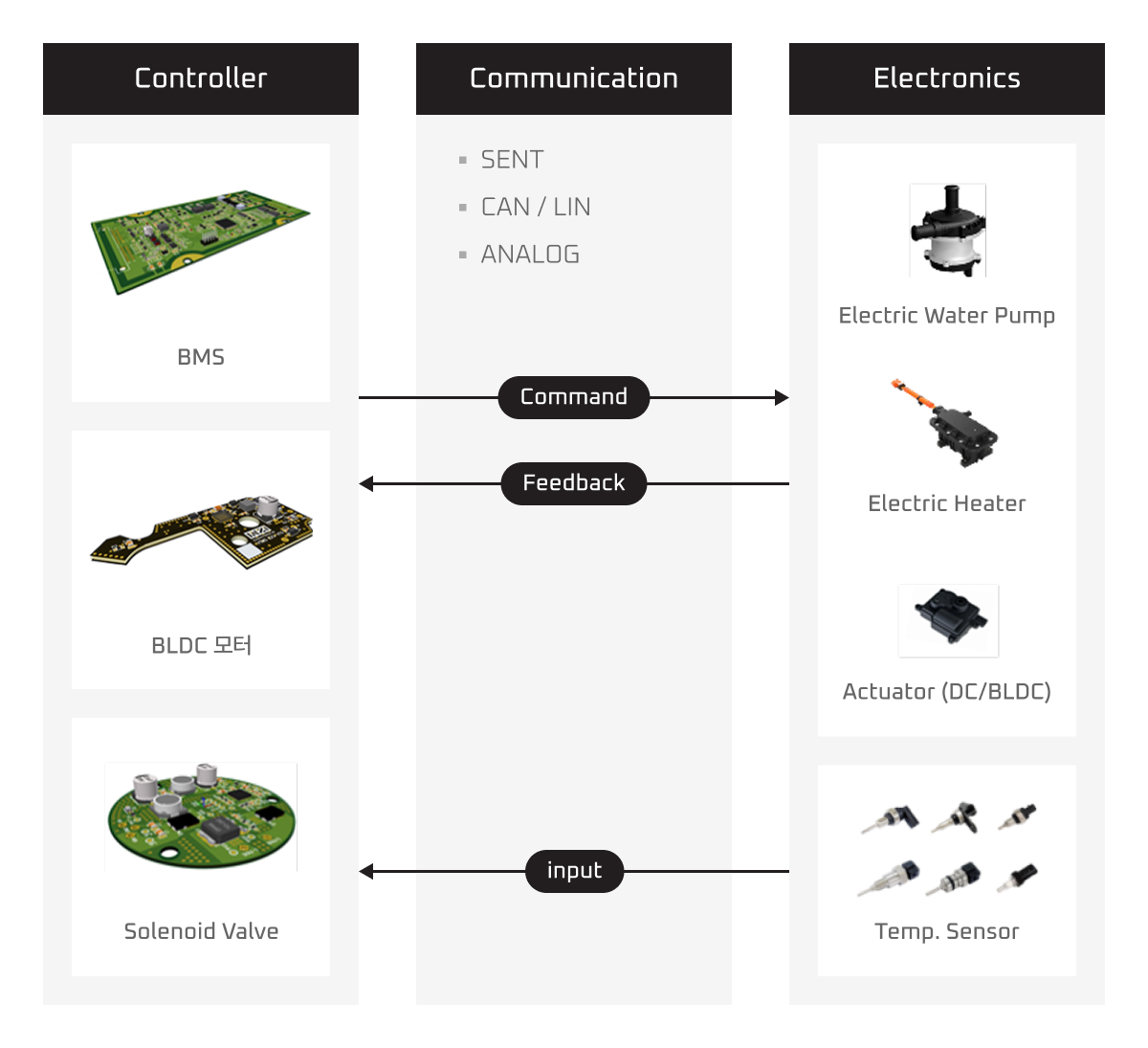

3Electronic/Control System

In response to the accelerating trend of electrification, we have secured capabilities in sensor and motor-based technology development and are focusing on developing controllers and control logic.

Change

4Engine Components

In an era where diverse powertrain vehicles coexist, for both internal combustion and hybrid vehicles, we continue to pursue lightweighting of commonly used engine components through ongoing research and development.

CAE

Control Logic & Controller

1SW Design Process

-

V-Process

-

Model-Based Design

-

Software Validation

2HW Design Process

-

Circuit Design

-

Analysis and Validation

-

System Verification

Test

TEST & Evaluation Strategy

-

Standard-Based Testing

and Evaluation -

INZI ITDP Testing

and Evaluation -

Mass Production

Durability Testing

-

Problem definition, root cause identification,

and effectiveness verification

of countermeasuresProblem-solving methodology

and product competitiveness enhancementINZI PSP

-

Testing and evaluation from the perspective

of failure physicsVerification of major failure causes

and critical damagesReliability

Evaluation -

Reduced reliability verification time

through accelerated durability testingAccelerated

Targeted Durability

Testing -

Operation of INZI Test Development Protocol

(iTDP) by productContinuous improvement based on durability

and reliability engineeringiTDP Operation

*iTDP : INZI Test & Development Procedure

R&D Excellence

National R&D Projects

INZI Controls is leveraging the “National R&D Funding” to develop new technologies and products.

| Development Objective | Technology Expansion | |||

|---|---|---|---|---|

| ICE | HEV/PHEV | BEV | FC MOBILITY | |

| CCV, Actuator, e-WP | ||||

| Battery Test Bench | ||||

| FCEV TMS Components & Module | ||||

| Battery Pack w/PCM | ||||

| FC Drone TMS Components & Module | ||||

| FC UAM TMS Components & Module | ||||

| Battery Pack, BMS | ||||

| Air Intake System, CCV | ||||

| EV TMS & Control | ||||

| Battery Module | ||||

| Battery Pack FC/Battery TMS | ||||

| Sensor Cleaning System | ||||